The First Production Printed 10R

The project began in 2024, while having finished the 10R Nationals with a loaned Diamond. After just over a year of model yacht racing I was beginning to realize the restrictions of not owning the boat you race, especially with a 10R. Knowing the costs both new and used of a competitive boat, I then realized that printing a hull could be an option, albeit far-fetched due to a 10’s unlimited weight potential. A sailor had attempted a printed 10 in Australia already, though the story’s documentation is short-lived, and so I had no evidence of whether or not it was possible.

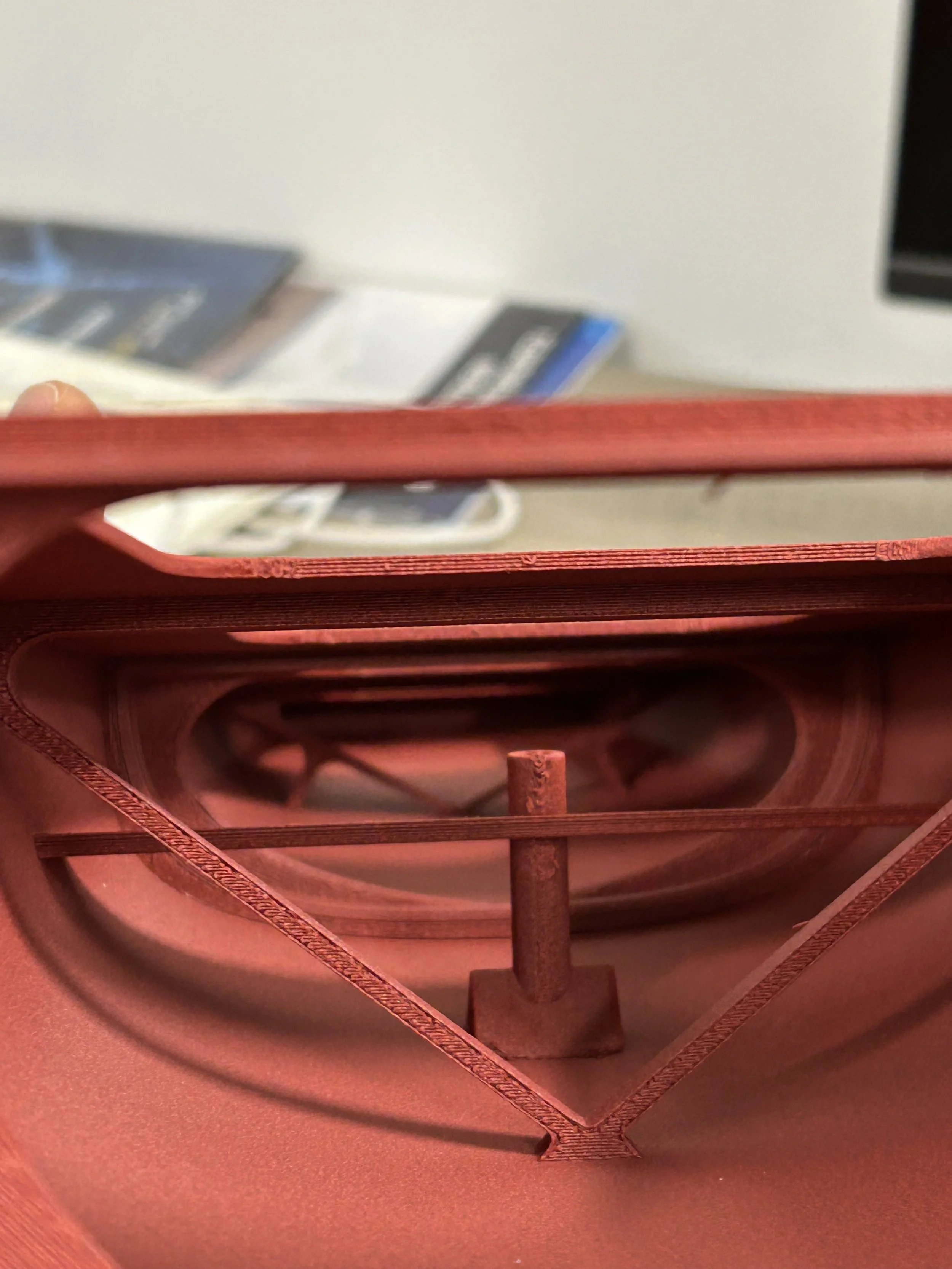

The first prototype was built under a GCSE project for Product Design at school. To satisfy the project parameters, I needed to make the design modular, however I was able to experiment with everything else. In order for the boat to have any chance at success it needed a performant design, and after reaching out to a number of builders Frank Russell (frankrusselldesign.com), the creator of the Phoenix 8 10R, returned with the Erebus, a design released in July 2024 and essentially a successor to the Phoenix (Spectre) 8. Frank kindly also provided a CAD model of the outside of the hull. From there it was divided into 7 sections to allow for a standard printer to fit the sections (256mm) and hollowed to a thickness of 2mm, and then 1. The modular hull proved extraordinarily stiff, however also incredibly heavy - in excess of 1500g. On a side note, I also messed around here with a no more than a crazy idea and curiosity - but ended up producing the a 3D printed Bow Bumper (first for production at least in the UK, unless anyone wants to correct me and that its already been done) using TPU 90HF from Bambu Lab. The hull raced in the last couple races of the ranking event in Early 2025 using flat bulkhead joins and socket head M3 Screws, and although suffering from some rig construction issues - another area I was inexperienced in - showed some good straight line speed. More importantly, it didn’t sink or break; two cards that were most certainly on the table. As soon as the GCSE construction phase finished in May 2025, I began designing a version 2, nicknamed ‘Murder By Numbers’. This design took the fundamental insides, a thinner hull and the same fittings from ‘Stealth’, the modular design, however lost over 300g through hollowing most of the parts. When I disassembled the hull for its parts, it proved way too strong, and I even failed to smash the fin box with a heavy pair of pliers. This was the first sign that I overcompensated for the strain on the hull. Murder By Numbers was printed with 1 wall and 5% infill for the printers among you, while stealth was printed with 2 walls and 10-15%. Both hulls were Bambu Lab PLA-CF, which is stiffer but less impact-resistant than PETG-CF. I did not sand or finish the hull, both due to the supposed shark-skin effect, but also for weight and strength. Through numerous emails to Frank, I finally arrived at a second finalized prototype design. I started printing it, intending for it to be raced by LMYC member Barrie Martin in 2026. A number of the sections needed re-printing due to fitting errors, but eventually a hull was put together with the same epoxy recommended for the new Proteus design, and proved incredibly stiff. I was expecting a bit of flex, perhaps a stiffer fin box, but it proved that idea completely wrong. Weighing in at 1228g, just 200g off of a 2008 Diamond in carbon, I was incredibly happy with the result. The bulkheads, due to being printed vertically, were able to sit completely flush with the next sections, without any sanding or altering, and didn’t really need glue to stay together. The hull will now race at the LMYC (London model yacht club) in Kensington Gardens into the new year, hopefully alongside some new production hulls. Some pictures of the hulls unjoined are below for the curious.

Once the hull has proven to be as competitive as I can make it, I think I will then begin working on a Marblehead, which will be a difficult fight with weight. Might need to wait until after university for that one. In the meantime, I also intend to experiment with a filleted fin insert, to soften the impact of drag around the contact point between the fin and the hull.

None of this would have been possible without the endless guidance and patience of all the members at the LMYC, as well as my teachers in the engineering department, and of course, Frank Russell.

Nick Brown

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!